Description

Price: $9.89

(as of Jul 17, 2024 10:15:27 UTC – Details)

Product Description

GreaseCo HeavyDuty Moly – 10 Pack of Grease Tube Cartridges

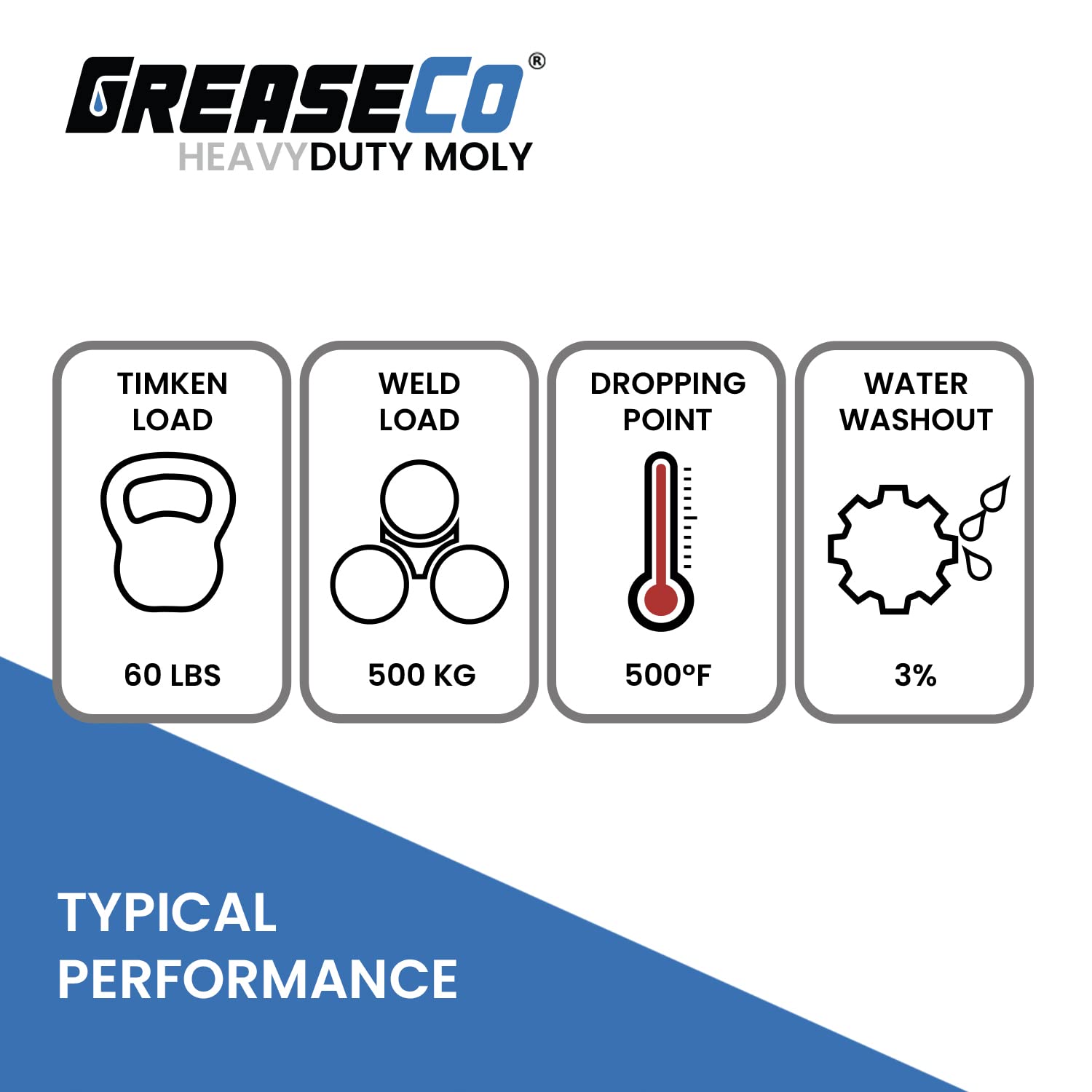

GreaseCo’s “molydbendum disulfide” HeavyDuty Moly grease has earned its spot in our comprehensive product line as a popular choice for applications requiring an additional layer of added moly protection. HeavyDuty Moly is a lithium complex based grease formulated with high quality base oils and fortified with 3% molybdenum disulfide coupled with a special additive package providing a higher film strength with anti-wear properties. The addition of 3% molybdenum disulfide provides this grease with an added armor-like film of lubricating solids.

This grease is designed to meet the heavy shocking loading requirements of many heavy industrial, construction (OEM) and mining equipment. HeavyDuty Moly provides fantastic overall protection against high temperatures and extends service life in parts subjected to extreme pressures and heavy shock loading. This grease will not easily washout under intense water ingress, allowing it to help prevent the formation of rust and corrosion.

Some common applications of GreaseCo HeavyDuty Moly grease typically include operations of extreme high pressure metal surfaces sliding against each other, often causing the pressure to become so great that the base oil held within a grease to be unable to penetrate or provide adequate lubricity. GreaseCo’s molydbendum is specifically engineered to leave behind “sheet like” layers of moly film for added protection during these instances; very similar to trying to run on a floor covered in baseballs cards.

Additional applications include excavator and loader bucket pins, bushings, king pins, ball joints, conveyor lubrication and applications where scoring, pitting and wear failures are a common problem. HeavyDuty Moly grease contains a balanced formulation of extreme pressure (EP) additives to provide protection against shock-loads, making it a perfect choice for fifth wheel lubrication found on semi-trucks, fleet maintenance and trailer hitches.

GreaseCo HeavyDuty Moly is part of our “blue” family/category of grease lubricants, as this line shares a common thickener of lithium complex based soap at their core. HeavyDuty Moly provides higher mechanical stability, allowing for greater performance characteristics required in open gear as well as metal on metal sliding applications.

High Performance Tacky Moly Grease

HeavyDuty Moly is a lithium complex based grease with high quality base oils and fortified with 3% molybdenum disulfide coupled with a special additive package providing high film strength, extreme pressure and anti-wear properties.

Wide Range of Applications

GreaseCo HeavyDuty Moly grease is designed to meet the heavy shocking loading requirements of many heavy industrial, construction (OEM) and mining equipment. This grease contains a balanced formulation of extreme pressure (EP) additives to provide protection against shock-loads, making it a perfect choice for fifth wheel lubrication found on semi-trucks, fleet maintenance and trailer hitches.

Heavy Duty Equipment Protection

HeavyDuty Moly grease provides protection against a wide range of temperatures and uses, extending service life in critical parts subjected to extreme pressures and shock loads. Additionally, this grease will not easily washout in the presence of water.

Why Choose GreaseCo Grease?

GreaseCo was developed through years of shared consumer frustration and a need for industry wide change. We have singular focus on providing a comprehensive lineup of greases that not only simplifies the purchasing experience but provides confidence and trust to our customers and future reliability of their equipment.

Protection Against Heavy Loads

GreaseCo HeavyDuty Moly grease is a lithium complex based grease with high quality base oils, fortified with a special additive package to provide higher film strength, extreme pressure and anti-wear properties. HeavyDuty Moly grease is a popular choice for heavy industrial metal on metal sliding applications.

Protection Against Galling and Seizure

GreaseCo HeavyDuty Moly grease exhibits an excellent weld load score and mechanical shear stability, protecting your equipment against the potential threat of galling or seizing. This provides our customers extended service life of vital equipment parts subjected to extreme pressures and heavy shock loading.

Protection Against High Temperatures

GreaseCo HeavyDuty Moly grease is formulated with an ISO 220 viscosity base oil, designed for high speeds, load carrying performance and ability to protect against high temperature applications.

Protection Against Water Ingress

GreaseCo HeavyDuty Moly grease exhibits excellent water washout characteristics, allowing it to stay in place and provide great protection against rust and corrosion.

Add to Cart

Add to Cart

Customer Reviews

4.5 out of 5 stars

111

4.5 out of 5 stars

59

4.6 out of 5 stars

214

4.1 out of 5 stars

21

4.6 out of 5 stars

82

Price

—

— $9.89$9.89 $11.99$11.99

—

Color

Black Black Red Green Amber

Thickener

Lithium Complex Calcium Sulfonate Lithium Complex Calcium Sulfonate Calcium Sulfonate

Base Oil Viscosity @ 40 cSt

220 460 460 220 460

Application Intensity

Heavy Severe Heavy Extreme Severe

Water Washout

Great Excellent Great Excellent Excellent

Dropping Point

Great Excellent Excellent Great Excellent

Weld Load

Excellent Excellent Excellent Excellent Excellent

Product Dimensions : 2 x 2 x 9.25 inches; 14 ounces

Item model number : HVDM-200-00014

Date First Available : October 21, 2020

Manufacturer : GreaseCo

ASIN : B08Z9X7FM5

Lithium Complex Moly Grease Fortified With 3% Molybdenum Disulfide (Moly Grease) for Heavy Duty Applications

Excellent for Construction Equipment/Caterpillar Specifications Requiring Moly For Pin & Bushing Applications

Applications: Excavators, Skid Steer Bobcat, Hydraulic Shovels, Bucket Pins And Bushings, Bulldozers

Universal Fit: Works with Lock N’ Lube, DEWALT, MILWAUKEE, Lincoln, Lucas, Ryobi, Bravex, GreaseTek, STEINBRÜCKE and Many More Manual and Automatic Grease Gun Brands!

Fifth Wheel (5th) Hitch Plates, Trucks and Trailers, King Pins, Pivot Pins, Trucks, Snow Plows, Vehicles, Spring Pins, Steering Linkages, Universal Joints, Utility Fleets, Water Pump Bearings, Demolition Equipment, Airport Support Vehicles And More!

Customers say

Customers like the performance, quality and value of the machine lubricant. They mention that it works well, is easy to use and is great value for the price.

AI-generated from the text of customer reviews

Reviews

About Us

At Autopartz.net, we are dedicated to being your ultimate online destination for all things automotive. Whether you’re a seasoned car enthusiast, a professional mechanic, or simply a vehicle owner looking to maintain and upgrade your ride, we’ve got you covered with a comprehensive selection of automotive products available on Amazon.

Newsletter

Sign up for our newsletter to get updated information, promo, and insight about automotive.

Reviews

Clear filtersThere are no reviews yet.